Startseite » Particle Metrology

The Q.ANT particle sensor uncovers the information you need, delivering real-time insights from your process through a web-GUI. Additionally, the API unlocks a wide array of possibilities.

Quantum-based particle sensors enable more sustainable methods, energy-efficient applications, and the highest quality. Welcome to the future of particle analysis!

The particle sensor measures the size, speed, and trajectory of particles in liquids and gases. Two versions are available for selection: The Q.P2 sensor analyzes particles in a range from 2µm to 50µm, while the Q.P20 sensor measures particles from 20µm to 700µm.

The intuitively designed web-GUI allows for real-time insights into your processes or material quality. The setup of the sensor is prepared and ready to use in just a few minutes.

Shape recognition and online installation of the sensor are the next milestones on our product roadmap. By involving customers early and maintaining close collaborations, we are working closely with the market on the next generation of sensors.

The Q.ANT particle sensor allows for immediate assessment of growth phases and critical cell attributes such as size and debris in cultivating bacteria, fungi, or algae. This analysis enhances the understanding of the microorganisms’ condition.

Quantum-based determination of size distribution simultaneously enables detection of unwanted agglomerates.

High-quality products from the metal, plastics, ceramics and cement industries require detailed knowledge of the raw materials, such as size and grain distribution – especially for 3D printing.

The precise analysis of pigment raw materials is the foundation for the development of colors and textures in the cosmetics industry.

Treating water requires precise knowledge about the nature of the contamination. The particle sensor can identify unwanted organisms and particles, thereby assisting in the refinement and purification process.

To ensure the quality and cleanliness of products, semi-finished products, and components, optimal environmental conditions and processes are necessary. The Q.ANT Sensor analyzes the efficiency of filters in wash and drain waters as well as the purity of process gases.

This converts the light in the superposition state back into linear light waves.

Data from the light measurement is fed from this output to software that uses it to generate information about the items measured.

The light in the superposition state is beamed to the measurement cell.

This focuses the laser beam and converts the incoming linear light waves into light in a superposition state.

Linear light waves strike the lens.

This generates the laser beam.

In this cell. the particles flow in gas, liquids or as powder through a translucent tube.

The light in the superposition state "illuminates" a particle simultaneously in several dimensions. This allows conclusions to be made almost immediately about the speed, size and position of the particle being examined.

This guides the laser beam.

The Q.ANT particle sensors operate using special states of light, so-called photonic superposition states. When such light waves strike a particle, it is illuminated simultaneously in multiple dimensions. This enables the acquisition of extensive information in a single real-time measurement, such as the speed, size, and trajectory of the particle. From this dataset, artificial intelligence will determine the shape of the particle in the future. We call this the Photonic Trick.

Prof. Dr. Volker Nestle

Head of Development LifeTech at Festo

The particle sensor is customized specifically for your application, ensuring that exactly what you need is measured, precisely where you need it. Our application engineers evaluate your requirements for optimal system settings. In the near future, this will also include shape recognition and online integration into your process.

At this year’s ACHEMA (Hall 11.0 Booth F50), the start-up Q.ANT is exhibiting the world’s first industrial-grade quantum sensor as a particle sensor. This can [...]

Q.ANT presents the world’s first quantum particle sensor for process technology at Achema. At the leading international trade fair for the process industry, Q.ANT will [...]

In a fascinating broadcast for coffee connoisseurs and those interested in technology, editorial journalist Frank Grotelüschen interviews Michael Förtsch and Maria Hohm about quantum sensor [...]

Customer Project Engineer

Q.ANT GmbH

Handwerkstr. 29

70565 Stuttgart

Germany

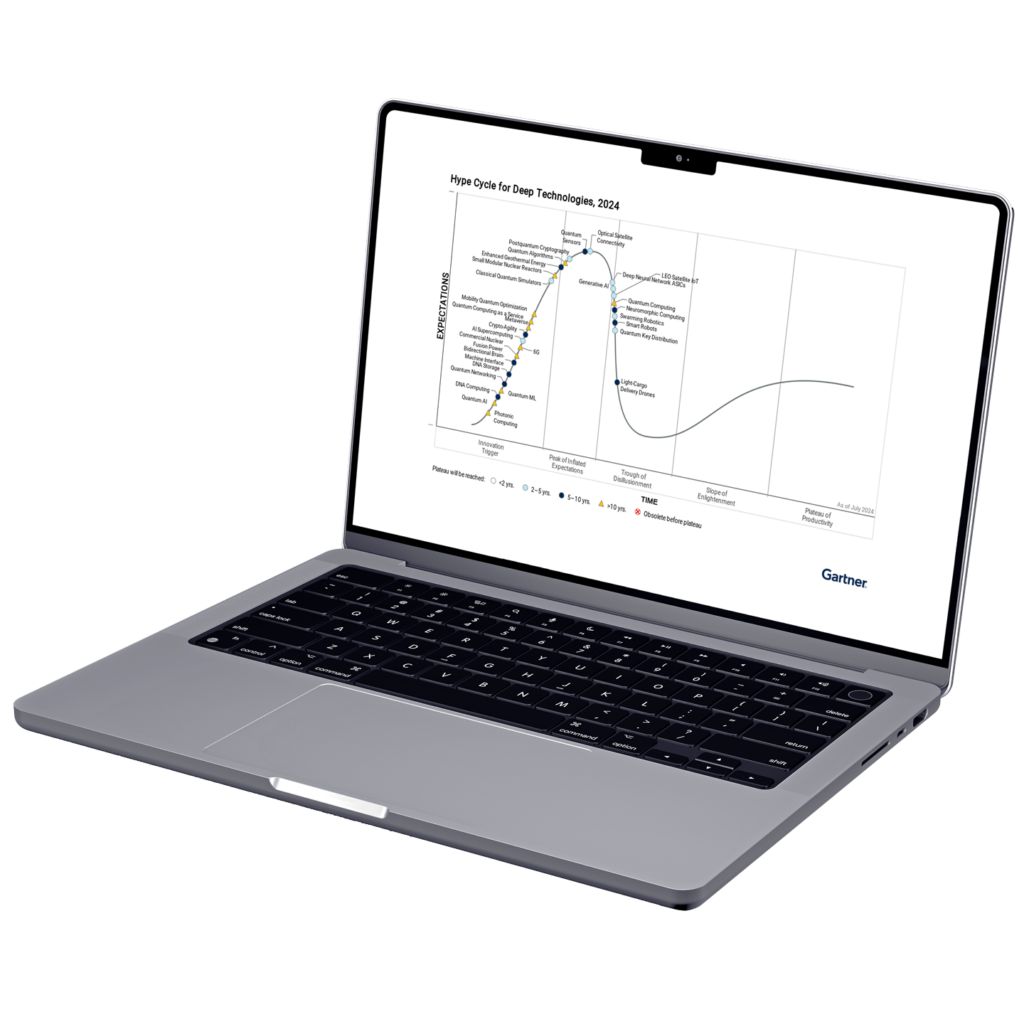

We provide exclusive access to the Gartner® Hype Cycle™ for Deep Technologies 2024 report. Learn how Photonic Computing and Quantum Sensors can transform future business and society.